Table of Contents

ToggleHave you ever wondered what SMT means and why it’s so popular in electronics manufacturing? SMT, short for Surface Mount Technology, is the process that makes modern gadgets like smartphones and laptops work. SMT describes how tiny components are mounted onto printed circuit boards (PCBs) to create devices that make living a lot easier.

In this blog, we’ll break down what SMT means, how it works, and why it’s very important.

What does SMT?

SMT stands for Surface Mount Technology. It’s a method used to attach components directly onto the surface of printed circuit boards (PCBs). The SMT technique replaced the through-hole technology technique. In through-hole technology, the component leads were inserted through holes in the circuit board.

The difference with SMT is that the components are soldered directly onto the surface of the PCB so it allows for much smaller components and denser circuit boards. SMT components, commonly called surface mount devices (SMDs), are most times smaller than their through-hole devices.

Some common types of SMT components are:

Resistors

Capacitors

Inductors

Integrated circuits (ICs)

Light-emitting diodes (LEDs)

These components are designed with small metal tabs or pins that sit flush against the PCB surface. The SMT components have a compact nature which allows for better use of space on the circuit board.

How does SMT work?

The SMT process works in a number of steps:

- Solder paste application: A thin layer of solder paste is applied to the PCB using a stencil. This paste contains tiny solder particles which are suspended in a flux.

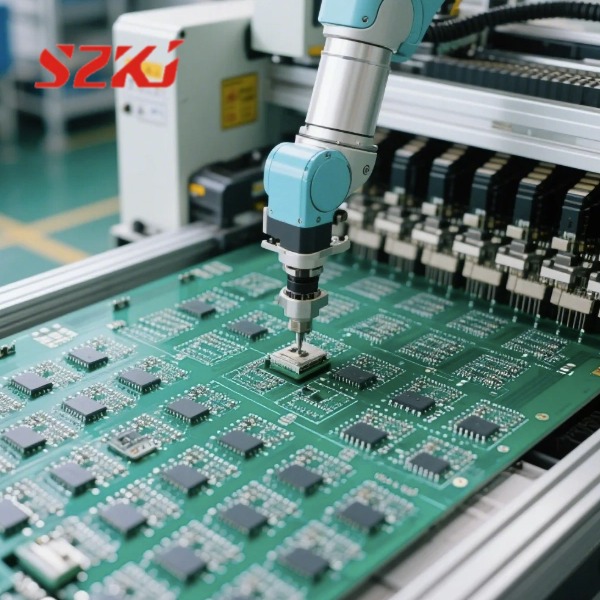

- Component placement: The SMT components are then placed onto the PCB using automated pick-and-place machines. These machines are very precise and can place thousands of components per hour.

- Reflow soldering: After component placement, the PCB with the placed components is passed through a reflow oven and the oven heats the board to temperatures high enough to melt the solder paste. This creates permanent electrical connections between the components and the board.

- Inspection: After reflow, the boards are typically inspected using

Automated optical inspection (AOI) systems or X-ray machines to make sure the components ae placed properly and the quality of the solder joints are good.

- Cleaning: Depending on the type of flux used in the solder paste, the PCB may be cleaned to remove any residues.

- Testing: Finally, the assembled PCBs undergo various electrical and functional tests to ensure they meet performance specifications.

Why is SMT important?

Now that we know what SMT means, let’s look at why it is important:

- Smaller components: SMT allows for much smaller components and denser circuit boards which help create portable electronic devices. This has led to the development of smaller, lighter, and more portable gadgets like smartphones, smartwatches, and ultra-thin laptops.

- Improved performance: The shorter connections between components in SMT designs means reduced electrical noise and better signal integrity. This leads to a strong overall performance of electronic devices.

- Cost-effective: While SMT equipment can be expensive initially, the process is well automated so it reduces labor costs and increases production speeds. This makes SMT cheaper for large-scale manufacturing.

The Bottom Line

In essence, what SMT means is a transformation in electronics manufacturing. Without SMT, we wouldn’t have the slim smartphones, lightweight laptops, or compact wearables that we rely on every day.

Why Choose Shanzhong Technology for SMT Production?

At Shanzhong Technology, we understand what SMT means to modern electronics manufacturing. Our standard SMT production lines are equipped with the latest technology to provide you with high-quality and affordable manufacturing of your electronic products.

Contact us today to learn more about how our SMT services can benefit your next project.