Table of Contents

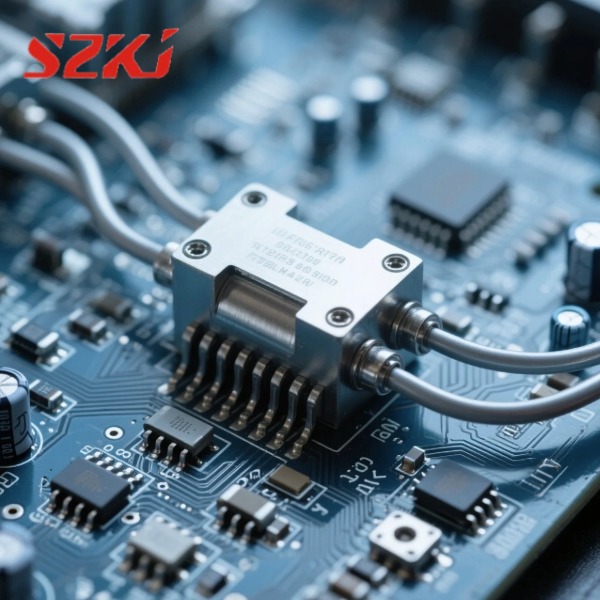

ToggleSurface Mount Technology (SMT) has emerged as a transformative force, reshaping the contours of electronic manufacturing. By enabling the production of intricate yet compact devices, SMT has set the stage for unparalleled advancements. A grasp of this technology and its nuanced processes is vital for enterprises seeking to optimize production cycles while elevating product precision. Below, we delve into the essence of SMT in manufacturing, deconstructing its workflow to illuminate its impact.

What is SMT in Manufacturing?

At its core, Surface Mount Technology entails the direct placement of electronic components onto the surface of printed circuit boards (PCBs). Diverging from traditional through-hole techniques—where drilling is indispensable for component integration—SMT emphasizes finesse and functionality, paving the way for devices that are both lightweight and compact.

The SMT in manufacturing underpins industries as diverse as consumer electronics, aerospace, and automotive, solidifying its status as the bedrock of contemporary electronics manufacturing.

The Importance of SMT in Electronics Manufacturing

The significance of surface mount technology lies in its transformative ability to bolster manufacturing precision, mitigate expenses, and accommodate complex engineering designs. Some key attributes include:

- SMT can create miniature electronic boards.

- Automated processes accelerate production.

- Fewer mechanical weak points lead to superior performance.

- Lower material usage and simplified workflows translate to cost-effectiveness.

Step-by-Step SMT in Manufacturing Process

Firstly, the inception of the SMT in the manufacturing process rests on meticulous PCB design tailored for surface mounting. Engineers employ specialized software to chart layouts dictating component placement.

A thin subcaste of solder paste ensures a strong electrical connection between the factors and the board. Automated pick and place machines precisely place each element on the board, following specific equals and measures for optimal delicacy and accuracy. The solder paste is also heated to secure the parts completely to the PCB.

A thorough examination is conducted to corroborate the correct positioning of all factors and the integrity of the solder joints. Advanced technologies, including Automated optic examination (AOI) and x-ray systems, are used to catch implicit errors and inconsistencies in the PCB board.

Styles similar to in-circuit testing and functional testing estimate the performance and trustability of each element to guarantee a high-quality affair. The final stage involves integrating fresh components like enclosures or connectors onto the PCB. As all factors are assembled, the board is packaged and prepared for shipping.

Challenges in SMT Manufacturing

While SMT in manufacturing significantly enhances efficiency in manufacturing, it also presents several challenges. The handling of small components necessitates advanced equipment, and any inaccuracies in the application of solder paste can compromise PCB performance. Furthermore, the initial setup costs for surface mount technology processes are typically considerable.

Conclusion

SMT in manufacturing has fundamentally transformed the landscape of electronics manufacturing. When executed accurately, each step facilitates remarkable efficiency and reliability.

For professionals either new to surface mount technology or seeking to optimize their processes, a comprehensive understanding of these steps is crucial for success in today’s dynamic electronics industry.