Table of Contents

ToggleThe PCB washing machine is an essential component in modern laundry appliances, controlling various functions and ensuring efficient operation. At its core, the washing machine PCB (Printed Circuit Board) houses a microprocessor that processes user commands and sensor inputs to manage different machine components. This advanced control system enables automation, efficiency, and safety in washing machines.

Understanding the structure, functions, and manufacturing process of washing machine PCBs is essential for both consumers and manufacturers looking to enhance the performance and longevity of their appliances.

Structure of a Washing Machine PCB

The PCB washing machine consists of several key components, each playing a crucial role in the system’s functionality:

- Microprocessor: Acts as the brain of the washing machine, processing input signals and executing predefined washing programs. It ensures that the machine runs efficiently by coordinating all components.

- Memory Modules: Stores software, user settings, and operational data, ensuring the correct execution of washing cycles. The memory also allows error codes and user preferences to be saved for future use.

- Input/Output Interfaces: Connects the PCB to user controls, sensors, and other electronic components, facilitating seamless communication between the machine’s parts.

- Power Supply Circuit: Regulates and supplies power to all PCB components, ensuring stable operation. It converts AC power into DC power suitable for electronic components.

- Clock Circuit: Maintains system timing, allowing precise control over washing cycles, delays, and synchronization of different processes within the machine.

Main Functions of a Washing Machine PCB

The PCB washing machine is responsible for various functions that enhance the appliance’s efficiency and safety:

- Motor Control:The PCB controls the washing machine motor, adjusting its speed and direction for different washing cycles such as washing, rinsing, and spinning. Modern PCBs allow variable speed control to optimize performance and reduce wear on the motor.

- Electromagnetic Valve Control: The PCB manages the water inlet and drainage system, ensuring that the right amount of water enters and exits the drum during different washing phases.

- Detection and Feedback System: Through advanced sensors, the PCB continuously monitors water level, temperature, load weight, and drum movement, allowing real-time adjustments to improve washing efficiency.

- Display and Indicators: The PCB communicates with the user interface, providing information on the current washing status, error messages, and user-selected washing programs. LED displays or LCD panels provide a clear and user-friendly interface.

- Safety Protections : Washing machines are equipped with various safety features, and the PCB plays a crucial role in ensuring these protections work effectively. Overcurrent, overvoltage, undervoltage, and overheating protection mechanisms prevent damage to components and enhance user safety. If an anomaly is detected, the PCB can trigger alarms or automatically shut down the machine to prevent further issues.

Manufacturing Process of a Washing Machine PCB

The production of a PCB washing machine involves several critical steps to ensure quality and reliability:

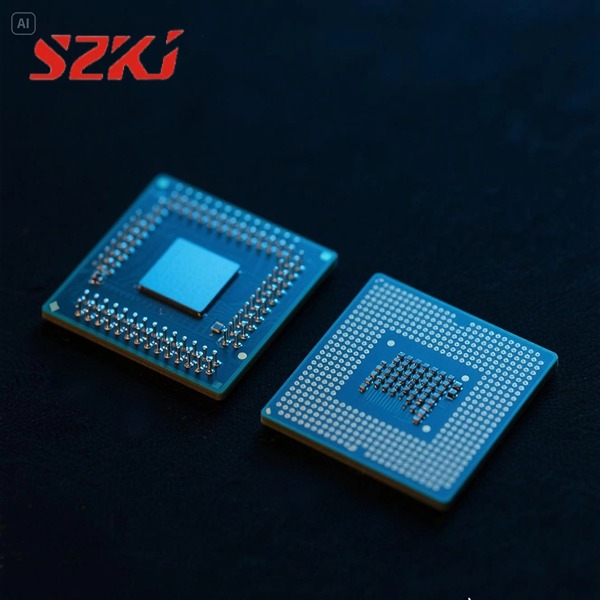

- PCB Fabrication: Circuit patterns are printed on copper-clad boards, creating the foundational layers of the PCB. This step involves precise etching and layering techniques to create a multi-layer PCB capable of handling complex washing machine functions.

- Component Soldering: Electronic components such as microprocessors, resistors, capacitors, and connectors are soldered onto the PCB following an automated process. Surface Mount Technology (SMT) is commonly used for high precision and efficiency.

- Testing and Debugging: The assembled PCB undergoes rigorous testing, including electrical performance tests, functional verification, and visual inspections to ensure flawless operation. High-voltage testing and simulation of real-world washing machine conditions are performed to guarantee reliability.

- Assembly and Packaging: Once the PCB passes all quality checks, it is integrated into the washing machine, connected to motors, valves, sensors, and displays. The final assembly process ensures that all components are properly connected, followed by a final system test before packaging and distribution.

Conclusion

The PCB washing machine is a fundamental part of modern laundry appliances, providing control, efficiency, and safety. As technology continues to advance, washing machine PCBs are becoming smarter, more energy-efficient, and more user-friendly. If you’re looking for premium PCBs for washing machines, visit SZKJ’s website to explore and place your order.

-768x768.jpg)