Table of Contents

ToggleSMT Products are the technological backbones of the communication industry. From assembling equipment to giving it a finishing touch, they have made production more effective and seamless than before. No more tedious through-hole assembling, as an SMT product can be used to automate every process.

But, what is SMT, and how exactly have their products helped to reshape the communication industry? Keep reading to find out

What is SMT?

Formally known as planar mounting, SMT is a modern technology that allows components to be directly fixed to PCBs using solder. SMT, which stands for Surface Mounting Technology, is a cutting-edge technology at the forefront of mounting leads without creating holes on the board.

The role of SMT in the communication industry can not be over-emphasized, as almost every modern communication device is produced using it. Think of the revolution of communication devices like mobile phones and laptops, from their initial size, weight, speed, and other performance to their present state. You will agree that SMT products have come to stay in the industry because we would rather stick to the new models than go back to the old ones.

The Role of SMT Products in the Communication Industry

SMT products are used to carry out the following in the communication industry;

- Automation

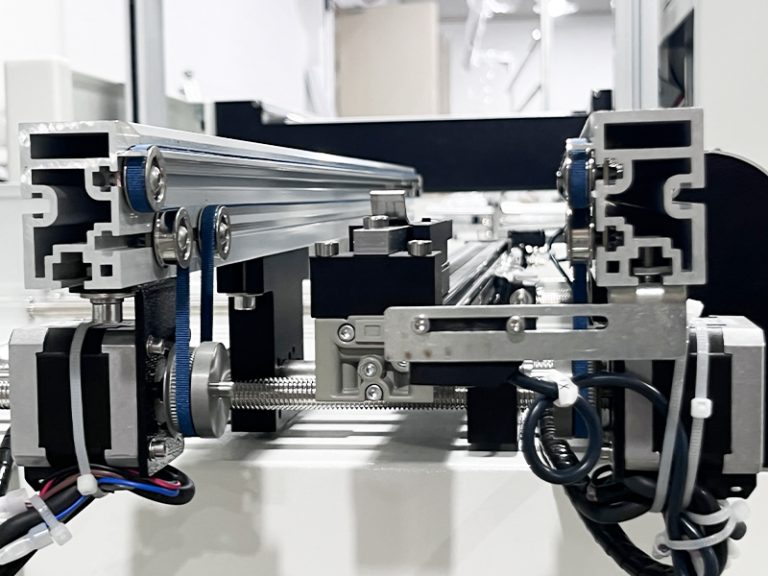

The era of drilling holes in the board and spending hours trying to place components on the board perfectly is gone. With SMT, you can place leads in the right spot with great precision without touching them. SMT products like the SZKJ SMT Pick and Place machine help to automate the whole process, reducing the time spent in production and maximizing efficiency.

- Miniaturization

Have you noticed how communication devices keep getting sleeker and smaller? It’s all thanks to SMT products and other cutting-edge technology used in their production. Normally, the holes drilled in the through-hole method are enough to limit space on the board, so you are likely going to need a bigger board. Unfortunately, a bigger board means larger devices. However, with SMT, smaller boards are required to achieve high component density. This, in turn, gives birth to communication devices with smaller sizes but higher functionality compared to old models.

- Flexibility

With SMT, communication devices can be designed to meet different designs. Unlike the through-hole method the manufacturers have to think about repairability while producing them, SMT produces devices with flexible designs. The device can be as flat or small as possible with a board that’s overpopulated with components.

- Cost Effectiveness

Because the processes are automated, communication devices like routers, phones, modems, etc, can be produced in bulk within a short duration. Reducing the cost of production and increasing efficiency as SMT products automate with high precision. Smaller components can mean less expenses as larger boards are known to be pretty expensive compared to smaller ones.

- Advanced Feature

Communication devices produced using SMT peripherals have advanced features, including enhanced electrical performance. Because the leads are shorter, parasitic effects and electromagnetic interference are reduced, automatically leading to a higher speed of the device. They also feature advanced thermal performance, as they don’t get heated up easily. Lastly, they are built to be compatible with other modern devices.

SMT Applications in the Communication Industry

Many devices used in the communication ecosystem today are directly or indirectly SMT products. Below are some of the unique applications of this technology in the communication industry.

- Base Stations

Base stations are key components of the communication industry because they help mobile devices access networks wirelessly. However, these base stations are manufactured by SMT due to the technology’s flair for higher integration and smaller sizes. The stations are small but highly reliable and efficient.

- Consumer Electronics

Most smartphones and tablets depend on SMT for their compactness and efficiency. Without it, we will still be stuck with ridiculously big phones, computers, and tablets that may not be as efficient as their sizes.

- Telecommunication Infrastuctures

The communication industry relies on infrastructures such as satellite communication equipment and fiber optic communication systems for the transmission of large data through long distances. To succeed in this transmission, minimal signal degradation and high bandwidth are sacrosanct. SMT provides the framework to manufacture these pieces of equipment.

- Switches and Routers

Routers and switches are critical network infrastructural components for managing and directing data flow. Without SMT, their production would have been tedious and impossible. The technology ensures stability and optimal performance.

- Internet of Things (IoT)

IoT devices rely on wireless modules, processors, and small sensors to function. SMT manufactures all of these.

Advantages of SMT in the Communication Industry

SMT has become a preferred choice for electronics manufacturers in the communication industry because of its numerous benefits. These include increased density support, reduced labor cost, enhanced production, and resistance to mechanical stress. Of these, the higher assembly density, which makes complex circuitry possible, stands out. The flexibility it guarantees in PCB designs also finds many applications in the communication industry, making it a widely used production technology.

Frequently Asked Questions

What are the materials used in SMT?

The major materials used in SMT include flux, a medium for heat transfer, adhesive, solder paste, and cleaning agents.

What is meant by SMT?

SMT is a process used in manufacturing industries to mount components/leads directly to the surface of a board.

What are the different types of SMT?

The types of SMT available today are wave soldering machines, pick and place machines, reflow ovens, reflow selective soldering machines, and stencil printers.

What is the meaning of SMT equipment?

SMT equipment is equipment used to automate surface mounting and printing of CCAs in industries to increase production efficiency and reduce costs.

What are the other names for SMT?

The other names for SMT include surface mount equipment (SME), surface mount assembly (SMA), surface mount components (SMC), and surface mount package (SMP).

Conclusion

When we talk about miniaturization, automation, flexibility, budget-friendliness, and enhanced performance of communication devices, we talk about SMT products. Thanks to SMT techniques, the communication industry has been graced by state-of-the-art devices to make communication easier. Indeed, SMT is in the present and future of the communication industry with cutting-edge technology to make huge differences.