Table of Contents

ToggleSMT Machine Functions: Active vs Passive Components

The surface-mount technology (SMT) process needs a high level of precision because of the multiple components involved. From capacitors to microcontrollers, all components must be placed correctly. That’s why knowing the difference between active and passive components is essential for a smooth production process.

Roles of Active and Passive Components on PCBs

In electronics, every component plays a role. Passive components do not need power to function. They include resistors, capacitors, and inductors. These regulate signals or store energy. They are small, simple, and often come in standard shapes and reels.

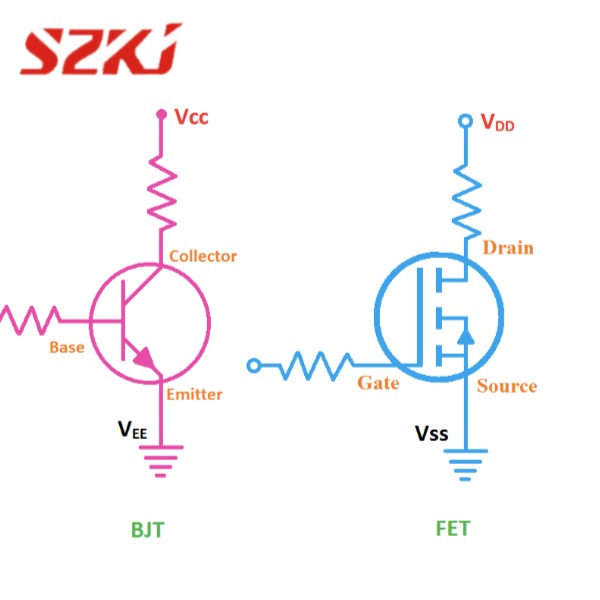

Active components need power. Transistors, integrated circuits (ICs), and diodes fall into this category. They amplify signals or switch power. They are complex in both function and form.

The difference between active and passive components shapes how they behave in a circuit. It also changes how machines place them on a board.

How SMT Machines Identify Each Component Type

Modern SMT machines use cameras and software to recognize parts. These machines can see component outlines and verify placement angles. They know where to place parts based on the program loaded into their system.

For passive components, machines pick and place using simple feeders. These parts usually share a standard pitch and package size, making automation easier. The SMT machine can move quickly through reels of 0402 or 0603 resistors with minimal calibration.

Active components need extra care. Their unique pins or shapes require custom trays or tubes. The vision system must verify orientation to avoid damage. Components like microchips or BGA packages need precise pressure and angle. That’s where the SMT machine slows down, checks alignment, and adjusts placement in real time.

Feeding Systems Adapt Based on Component Complexity

Passive components use tape-and-reel feeders. These feed hundreds of parts per minute. The feeding system pulls one part after another, letting the machine work fast.

Active components may need stick feeders or trays. These carry fewer parts. Sometimes a machine needs a robotic arm to lift and rotate the part before placement. This slows the process, but it protects the part.

The difference between active and passive components affects throughput directly. SMT line managers often plan the machine layout and feeder slots based on part types to reduce bottlenecks.

Placement Speeds and Tolerances Vary by Component Type

Passive components tolerate more placement error. They do not have sensitive pins or thermal properties. The SMT machine can run them at high speeds with minor corrections.

Active components need tighter control. SMT machines slow down and increase optical checks. High-density PCBs often require the use of multi-nozzle heads for efficiency. But when placing ICs, one head may focus only on alignment and pressure, ensuring no solder bridges occur.

Understanding the difference between active and passive components allows manufacturers to choose the right machine specs and nozzles.

How Setup and Programming Are Affected

When programming an SMT machine, engineers use data files like the Bill of Materials (BOM) and CAD data. For passive components, standard footprints and feeders reduce setup time. For active parts, engineers must define pin orientation, rotation angles, and height settings.

A misstep here can cause the machine to place the part backward or with too much force. That risk is higher with active parts due to their complexity. Training operators to distinguish the two types early helps reduce the errors.

SMT lines depend on accuracy. The difference between active and passive components defines how machines pick, place, and verify each part. A smart SMT machine setup considers these differences to ensure smooth production.

To build high-quality boards, SZKJ choose the right feeders, placement heads, and programming settings.