Table of Contents

ToggleSMT is not just a manufacturing process, but it also represents a significant shift in how electronic components are assembled such as tiny chips. The power supply industry uses SMT technology to enhance efficiency in production, Precision, and Quality Control.

Surface Mount Technology (SMT) allows for the direct placement of components on the Printed Circuit Board (PCB) without drilling holes and makes the chip mounter process faster and simpler. This technology is very important for today’s electronics.

What is Surface Mount Technology (SMT)?

What is Surface Mount Technology (SMT)?

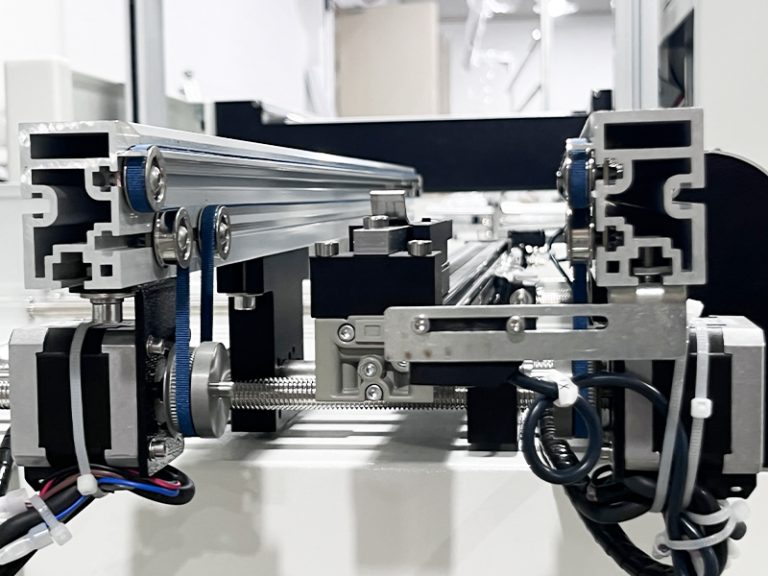

Surface Mount Technology (SMT) is an automated technique for placing chips directly onto the surface of a PCB. SMT allows circuits to be smaller, lighter, and more complex. The process uses advanced machines such as chip mounters, screen printers, and adhesive dispensers. These machines help place each part in the exact spot. SMT makes the production of electronics more efficient and faster.

Why Does the Power Supply Industry Need SMT Placement Machines?

Here are some reasons why SMT placement machines are needed in the power supply industry.

- High Placement Accuracy: SMT placement machines provide accuracy in placing the chips on the printed circuit boards. This will ensure that the chips are positioned correctly.

- Reduced Defects Rates: The SMT placement machines reduce the rates during manufacturing. These machines apply the right amount of pressure and alignment.

- Lower Labor Costs: These machines also help to minimize the labor cost and fewer workers are needed for manual assembly. Ultimately this will help to save money and improve the business profit.

- Material Efficiency: The right placement of the chips can reduce waste. These machines accurately place chips and ensure that materials are used effectively.

- Cost-Effective: Investing in SMT placement is cost-effective. The combination of reduced defect rates, lower labor costs, and improved material efficiency leads to supply units more quickly.

Why Chip Mounting is Important?

Chip Mounter is the process of placing or attaching the chips on the Printed Circuit Boards (PCBs). Chip Mounted is very important. In that case, if the chip is not perfectly placed or mounted, it cannot work properly or there is a chance that it may stop working over time. During working, chips can get hot and a strong mount helps with a heat control, so the device doesn’t overheat.

Advantages of SMT Patch Technology in the Power Supply Industry

Here are some of the advantages of SMT patch Technology in the Power Supply Industry:

- Improved Reliability

- Miniaturization

- Higher Component Density

- Faster Production

- Better Thermal Management

- Increased Durability

- Enhanced Performance

How Chips are Mounted by using SMT?

How Chips are Mounted by using SMT?

Let’s discuss how the chip mounted works.

- Clean the Circuit board by using the SMT Cleaning Machine and hold the chip with a chip mounter.

- Apply the solder paste where the chip is placed. The 1000mm Cooling Conveyor for PCB is used after soldering for a solid solder joint.

- After cleaning, check the board to ensure that the chip is correctly placed and working.

Common Use of Chip-Mounted Boards in Electronic Devices:

Chip-mounted Devices are used on various electronic devices we use daily. Some of the devices include;

- Smartphones

- Television

- Gaming Consoles

- Laptops and Computers

- Medical Devices.

Summary

Surface Mount Technology plays an important role in the power supply industry. It enables the efficient placement of chips on PCBs and leads to improved quality, faster production, and more reliable power supply units. It also allows for miniaturization, better thermal management, and higher component density. Moreover, the Chip Mounter ensures that each component is accurately placed. Overall, SMT technology is a cost-effective solution that improves the manufacturing speed and performance in the power supply sector.Welcome to SZKJ for details.