Table of Contents

ToggleSurface Mount Technology (SMT) is the backbone of modern electronics manufacturing, enabling precise, high-volume assembly of electronic components onto printed circuit boards (PCBs). A complete SMT production line consists of various pieces of specialized equipment that ensure the efficiency, accuracy, and quality of the final product. In this article, we will explore the key machines and equipment in a full SMT production line, highlighting their roles and contributions to the process.

1. Board Loading Machine (Upboard Machine)

The first step in any SMT production line is loading the PCB onto the system. This is achieved with the board loading machine, which automatically places the PCB onto the conveyor belt for further processing. The loading machine ensures smooth and consistent flow throughout the assembly line, initiating the process of SMT in electronics.

2. Board Unloading Machine

After all assembly tasks are completed, the board unloading machine is used to remove the finished PCBs from the production line. This equipment ensures that the PCBs are properly handled and transferred to the next stage of production, such as testing, packaging, or shipment. It plays a critical role in ensuring the smooth operation and efficiency of the entire SMT production line.

3. Solder Paste Printer

The solder paste printer is one of the most important pieces of equipment in the SMT production line. It precisely applies solder paste onto the PCB pads using a stencil. The quality and accuracy of the solder paste application are crucial, as they directly impact the success of the component placement and soldering processes. High-quality solder paste printing ensures that the components can be securely attached to the board during the next steps of SMT in electronics.

4. SPI Inspection Machine

After the solder paste is applied, an SPI (Solder Paste Inspection) machine is used to inspect the paste quality. The SPI machine checks for defects such as insufficient or excessive solder paste. By identifying these issues early, the SPI machine ensures that the rest of the assembly process goes smoothly, preventing defects and improving the overall quality of the finished product. This inspection is an essential step in maintaining the high standards of SMT in electronics production.

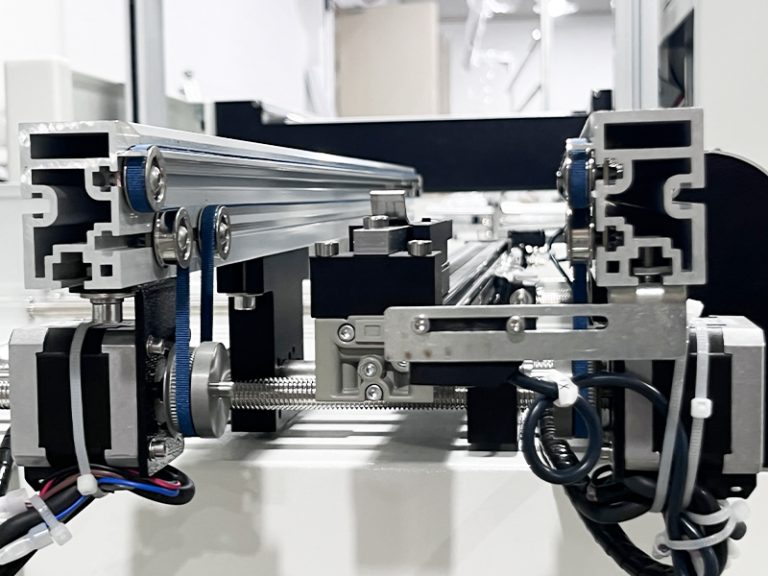

5. Pick and Place Machine (SMT Placement Machine)

The pick-and-place machine is the heart of any SMT production line. This machine picks up and places the electronic components onto the PCB with high precision. Using advanced robotic arms or similar technology, the pick and place machine places components according to the design specifications. Its speed and accuracy are critical to the efficiency and success of the SMT process.

6. Conveyor and Manual Workstation (Connection Station)

Before the PCB enters the reflow oven, it is often passed through a manual workstation, also called a connection station. Here, operators ensure that all components are correctly positioned and make any minor adjustments necessary before the reflow soldering process. This stage is essential for checking and correcting any issues before proceeding further in the SMT production line.

7. Reflow Soldering Oven

Reflow soldering is a critical step in the SMT process, and the reflow oven plays a key role in this phase. The oven heats the PCB to a precise temperature to melt the solder paste and create strong electrical connections between the components and the PCB. The reflow oven ensures reliable solder joints and is vital for the integrity of the finished product.

8. AOI (Automated Optical Inspection) Machine

The AOI machine is used to inspect the PCBs after soldering. It employs high-resolution cameras to scan the board for defects such as misaligned components, insufficient solder, or other errors. AOI is an essential step in ensuring the quality of the final product and maintaining the high standards required in SMT in electronics manufacturing.

9. X-Ray Inspection Equipment

For even more detailed inspection, X-ray inspection equipment is used to detect hidden defects. X-ray machines provide a non-invasive way to inspect the inner layers of the PCB, ensuring that no defects are missed. This is especially important in ensuring that the components are properly soldered and the board functions as intended.

Conclusion

A full SMT production line comprises various essential equipment designed to optimize the manufacturing process and ensure high-quality output. From the board loading machine to the X-ray inspection equipment, each piece of machinery plays a vital role in the assembly of electronic components. At SZKJ, we provide reliable PCB machines that ensure precision and efficiency at every stage of the SMT production line.