Table of Contents

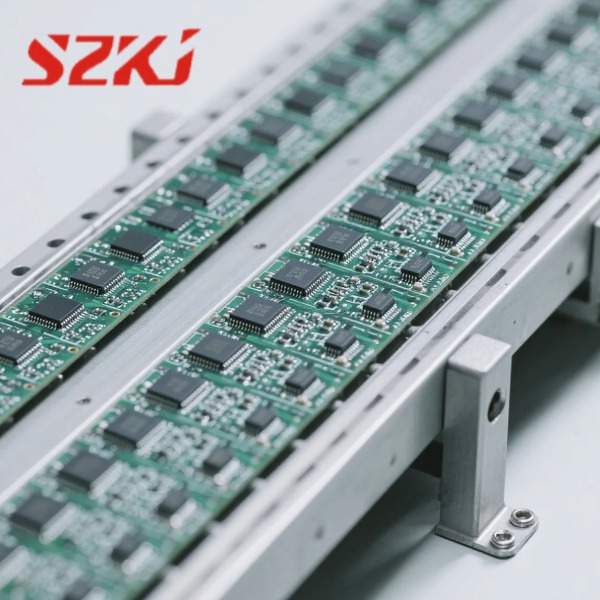

ToggleA pick-and-place machine, particularly an SMT pick and place machine, plays a key role in electronics manufacturing. It automates the precise placement of surface-mount components onto printed circuit boards (PCBs), dramatically improving speed and accuracy. These machines are vital for producing high-demand electronics, such as consumer devices, automotive components, and telecommunications equipment.

How SMT Pick and Place Machines Work

How SMT Pick and Place Machines Work

The SMT pick and place machine automates the intricate process of picking components from a tape or tray and placing them onto a PCB. Robotic arms pick components and position them precisely as per the board’s design, reducing manual errors. With electronics becoming increasingly complex, these machines can handle even the smallest components with speed and accuracy, vital for today’s production needs.

Key Conveyor Systems for SMT Production Lines

In any SMT production line, conveyor systems help optimize the flow of PCBs. These conveyors are essential for keeping the line running smoothly:

- Wave Exit Conveyor for PCB: This conveyor moves the PCB after the wave soldering process, ensuring seamless transitions to the next stage.

- Lowering Gate Conveyor for PCB: This conveyor allows operators to temporarily lower the gate, providing easy access to the production line for maintenance or adjustments.

- PCB Connection Conveyor: Connecting different stages of production, this conveyor ensures smooth transitions between the SMT pick and place machine and other equipment, such as reflow soldering machines.

- 90-Degree Turning Conveyor for PCB: In cases where space is limited or the factory layout requires, this conveyor allows for a directional change of PCBs to optimize the production flow.

Applications and Benefits of SMT Pick and Place Machines

Applications and Benefits of SMT Pick and Place Machines

SMT pick-and-place machines are used across industries such as automotive, telecommunications, and consumer electronics. The main benefits include:

- Increased Speed: Automating component placement accelerates production, allowing for higher output in less time.

- High Precision: These machines place even the smallest components with high accuracy, reducing errors and waste.

- Cost Efficiency: By minimizing errors and optimizing component use, these machines reduce overall production costs.

Enhanced Productivity with SMT Machines

An SMT pick and place machine can handle thousands of components per hour, ensuring consistency in high-volume manufacturing. Integrating peripheral conveyor systems such as the wave exit conveyor, lowering gate conveyor, PCB connection conveyor, and 90-degree turning conveyor further enhances the efficiency of the production process. These systems work together to prevent bottlenecks and ensure the smooth movement of PCBs through various stages of production.

Conclusion

The SMT pick and place machine, in combination with conveyor systems like wave exit conveyors, lowering gate conveyors, PCB connection conveyors, and 90-degree turning conveyors, forms the backbone of modern electronics manufacturing. Together, these machines and systems enhance production speed, accuracy, and efficiency, helping manufacturers meet the growing demand for more complex electronic devices. Investing in both an SMT pick and place machine and the right conveyor systems can optimize the entire manufacturing process.

For more information on these machines and conveyors, visit SMT Manufacturing, where you can explore a variety of options to enhance your production capabilities.