Table of Contents

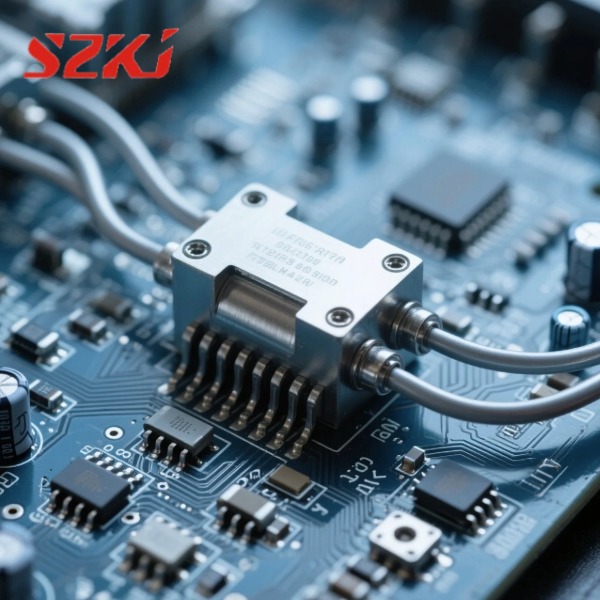

ToggleSurface Mount Technology (SMT) manufacturing is a widely used process for assembling electronic components onto printed circuit boards (PCBs). This process replaces the older through-hole technology, where leads are inserted through holes in the board. In SMT manufacturing, components are mounted directly onto the surface of the PCB, which allows for more compact and efficient circuit designs.

SMT Pick-and-Place: Component Feeding and Machine Vision

At the core of SMT manufacturing is the “pick-and-place” process, where the components are automatically fed and placed onto the PCB. Machines with advanced machine vision systems are used to accurately pick up small components from reels or trays and place them precisely on the board. The machine vision system ensures that the components are correctly aligned and oriented, which is crucial for the performance and quality of the final product. This automated process minimizes human error, increases efficiency, and speeds up production.

Reflow Oven and SMT Soldering

Once the components are placed on the PCB, the next crucial step in SMT manufacturing is the reflow soldering process. This is typically done in a reflow oven, where the board is passed through a temperature-controlled environment. The solder paste applied earlier melts and bonds the component leading to the PCB, ensuring electrical connections are established. The reflow oven’s temperature profile is carefully controlled to ensure that each component is soldered correctly without causing damage to sensitive parts of the PCB.

Basic SMT Process Steps

The SMT manufacturing process follows a well-established sequence of steps to ensure the quality and reliability of the final product:

- Stencil Printing (Screen Printing): The first step involves applying a precise amount of solder paste onto the PCB using a stencil. This paste will later be used to bond the components to the board during reflow soldering.

- Dispensing (Glue Application): In some cases, adhesive or glue is dispensed onto the PCB to help secure components in place before they are soldered.

- Pick-and-Place: The machine places the components onto the PCB, guided by the machine vision system to ensure accuracy.

- Reflow Soldering: The board passes through the reflow oven, where the solder paste melts and forms strong electrical connections.

- Cleaning: After soldering, the board is cleaned to remove any residual flux or soldering contaminants.

- SPI (Solder Paste Inspection): A critical step that involves checking the quality and amount of solder paste applied to the board before the placement of components.

- Inspection: Automated optical inspection (AOI) systems are used to detect any defects or misalignment of components.

- Rework for Defects: Any defects found during inspection are corrected, often using automated systems or by reworking the PCB manually.

AOI Principle and Advantages

Automated Optical Inspection (AOI) is a non-destructive testing technique used in SMT manufacturing to identify defects in the soldering and placement of components. AOI systems use high-resolution cameras to inspect the PCB for defects such as missing components, incorrect placement, and soldering issues. The system then compares the image to a known good reference and flags any discrepancies.

The advantages of AOI in SMT manufacturing include:

- Increased Accuracy: AOI ensures precise inspection of the PCB, detecting even the smallest defects that might go unnoticed by the human eye.

- Faster Detection: Defects can be identified in real time, reducing the need for manual inspection and speeding up the production process.

- Reduced Scrap and Rework: By detecting defects early in the process, AOI helps reduce the amount of scrap and rework, thus saving costs and time.

Conclusion

SMT manufacturing is a critical process in modern electronics production. By using advanced technologies like pick-and-place machines, reflow ovens, and AOI systems, SMT manufacturing ensures high-quality, efficient production of PCBs. The step-by-step process, from stencil printing to inspection, guarantees the reliability and performance of the final product. Whether for consumer electronics, automotive systems, or industrial equipment, SMT manufacturing plays a key role in shaping the electronics industry.