Table of Contents

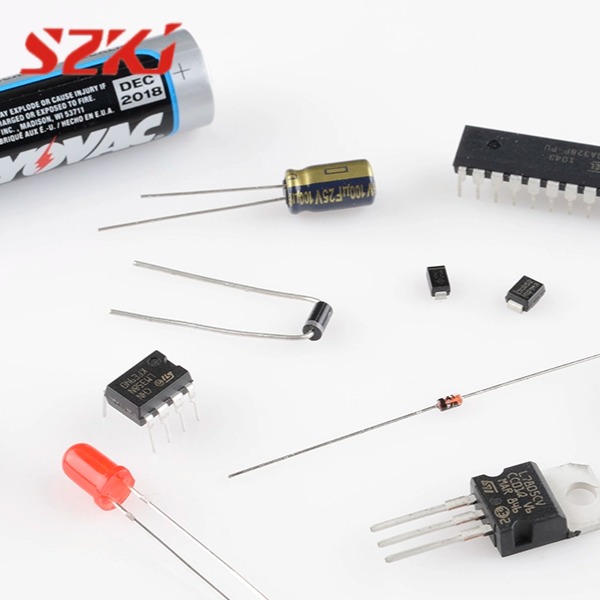

ToggleSurface-Mount Technology (SMT) is a process of making electronic circuits by mounting and placing components directly onto the surface of printed circuit boards (PCBs). SMT has revolutionized the electronics manufacturing industry, reducing product size, time-to-market speed, and cost of production. This blog discusses the key aspects of SMT electronics manufacturing, its benefits, and its impact on the electronics industry.

What is SMT?

In SMT the components are soldered directly to the PCB surface because of missing holes, hence very compact. Then, in classical electronic assembly, the leads of the components are introduced into holes on the PCB and then soldered. SMT is a method of sticking electronic components onto the PCB’s surface in electronics assembling.

Unlike the technology of through-hole, as there is no poking the component into holes but placing the device directly on the surface of the PCB, a more compact design is done in this way and has faster assembly speeds with cost reduction.

In SMT electronics manufacturing, SMT is highly utilized for the production of small electronic devices such as smartphones, computers, and medical appliances. It provides automated assembling that offers a lot of precision and efficiency during the whole production process.

Key Characteristics of SMT

Surface-Mount Technology (SMT) is quite highly regarded for its essential characteristics, which make the electronic assembly efficient and compact:

- High-Density Assembly: Through SMT, one is able to place components of a PCB at a far higher density than in a traditional method. This allows the creation of smaller, more powerful devices without sacrificing performance, especially appropriate for compact consumer electronics.

- A great degree of automation: The entire SMT process is dependent more heavily on machines to achieve the placement of components, soldering, and even inspection. Automation results in quicker production with fewer costs in labor and much more precise assembly, contributing to higher production rates.

- High Flexibility: SMT provides flexibility in design and manufacturing. It can accommodate a wide range of component sizes, from tiny resistors to larger components like connectors, allowing for versatile product designs across various industries, including automotive, medical, and telecommunications.

- Miniaturization: One of the most important advantages of SMT is that it supports miniaturization. The smaller components may be placed closer together, reducing the size of the PCB, and thus making possible much more compact and lightweight devices.

- Automated Placement: SMT accommodates pick-and-place machines that can accurately and rapidly mount components to a PCB. No human errors were found in the placement process, thus offering efficiency and reliability over traditional hand assembly.

- Two-Sided PCB Assembly: The two sides of a PCB can be populated using SMT, thus increasing the usability of board space. A two-sided assembly maximizes the surface area and finds suitability in products that are used for high functionalities in the smaller form factor.

- How Does SMT Work

There are many significant steps of the SMT electronics manufacturing process:

The Surface-Mount Technology (SMT) process involves several detailed steps in ensuring the proper and reliable mounting of electronic components onto a printed circuit board (PCB). Here are some more in-depth explanations for each of the stages mentioned:

1. Application of Solder Paste

Applying solder paste is the first step in SMT assembly. Solder paste is a mixture of small-sized metal solder balls and flux. Flux acts as an adhesive, as well as a conductor. A stencil is then used to apply solder paste precisely onto the pads on the PCB where components are to be placed. The paste is essential for this step because it will keep the components in place for the subsequent soldering. The flux within the paste helps the soldering process by cleaning the PCB pads and not allowing oxidation in the reflowing process.

2. Component Placement

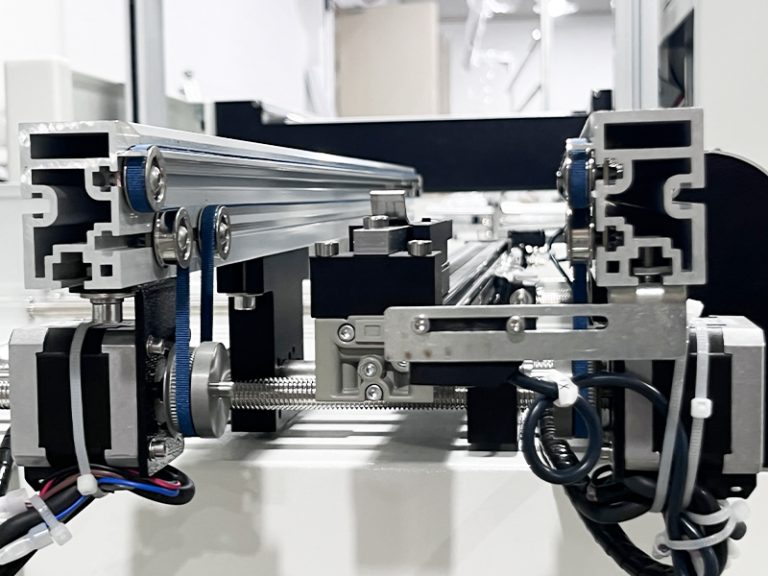

Once the solder paste is applied, the next step involves positioning the electronic components onto the PCB. High-speed pick-and-place machines, equipped with robotic arms that pick up components from reels or trays and place them on the pads covered with solder paste, do. Such machines are programmed to pick up and place each component in its correct position and orientation. Advanced pick-and-place machines are capable of processing thousands of components every hour, making them essential for large-scale production.

3. Reflow Soldering

After the installation of components on the PCB, the assembly is taken to the reflow oven process. In reflow, the PCB is heated up to a particular temperature. This causes melting of the solder paste which then cools down. This, therefore, results in the formation of solid solder joints between the components and PCB pads. The reflow oven utilizes a temperature profile that is carefully controlled in such a way that it increases and decreases the heat to avoid damaging sensitive components.

4. Inspection and Test

After the reflow soldering process, the PCB assembly undergoes a series of inspections and tests to ensure its quality and functionality. AOI machines can visually check the solder joints for any defects such as less solder, misaligned components, or solder bridges that create short circuits between two adjacent pads. Cameras and software are attached to AOI machines, allowing them to compare the actual assembled PCB with pre-set design data for any mismatch.

Best SMT Electronics Products

- SMT Cleaning Machine PCB-350-SZ

PCB-350-SZ Online Cleaning machine for heavy-duty cleaning needs in SMT manufacturing. The product cleans the PCB from both sides with accurate ESD anti-static control at below 50V, patented rollers, and a 99% cleaning rate.

- Features of PCB Connection Conveyor

The PCB Connection Conveyor is provided with Mitsubishi PLC programming for efficient and accurate operation. The SMT electronics manufacturing of PCB Connection Conveyor has power with a stepper motor along with customizable flow direction, overhead LED inspection lighting and SMEMA compatibility.

- Bare PCB Boards Vacuum Loader Features

The Vacuum Loader includes a Panasonic PLC touch panel, selectable loader, and bypass modes, with a safety visual window. It comes with a strong vacuum system, stack-empty alarms, rail width adjustment, and a PCB counter for efficiency.

Conclusion

Surface-mount technology has transformed the way electronic devices are manufactured. Indeed, SMT electronics manufacturing will remain a benchmark for innovation as it creates a future for the electronics industry through better technologies.