Table of Contents

Toggle Conveyor systems are among the most critical necessities in today’s SMT production lines. Organizations and factories that manufacture electronics products rely on conveyors to facilitate the movement of printed circuit boards (PCBs) and product components to, from, and within production lines.

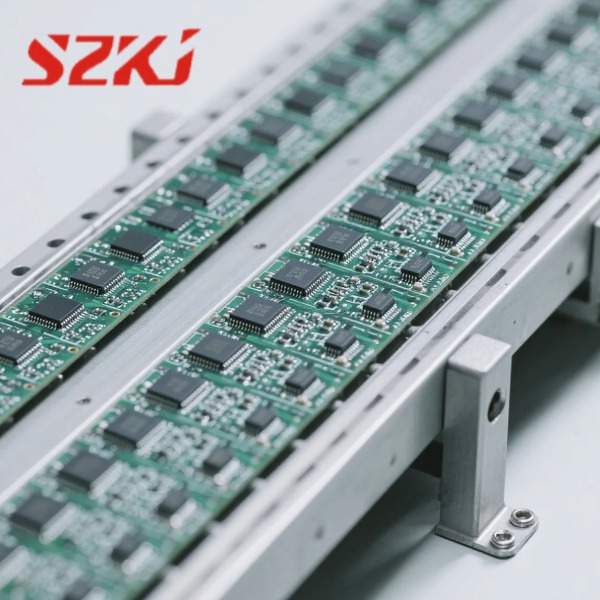

Conveyor systems are among the most critical necessities in today’s SMT production lines. Organizations and factories that manufacture electronics products rely on conveyors to facilitate the movement of printed circuit boards (PCBs) and product components to, from, and within production lines.

With knowledge and skills in assembly conveyors, manufacturers can enhance their manufacturing process lines, improve product quality, and reduce costs. However, what rolls through the conveyor assembly and how it can increase SMT production is still a question that requires an answer.

This article provides an in-depth understanding of conveyor assembly and offers practical methods and tools to optimize your conveyor processes to achieve maximum production capacity.

Why is Conveyor Assembly Important in SMT Manufacturing?

Increased Efficiency: The conveyor assembly is the core part of the entire SMT production line, responsible for transferring PCB boards (printed circuit boards) from one process flow to the next process flow, eradicating the need for many workers and hence saving cost and time.

Enhanced Quality: The stability of the conveyor belt directly affects the positioning accuracy of the PCB board during the transmission process. If the positioning is inaccurate, errors may occur in the subsequent patch and welding links, thus affecting the quality of the product, meaning improved end-product quality.

Improved Ergonomics: In this case, by reducing the physical contact with the materials, the conveyor system minimizes the physical strain and makes the working environment safer for the workers.

Optimized Production Flow: Conveyor belt assembly can flexibly adjust the transmission speed and process layout to adapt to different production rhythms and process requirements.The assembly conveyors if well designed can help elevate workflow patterns and reduce congestion, hence an added advantage of efficiency.

Key Considerations for Conveyor System Implementation:

Key Considerations for Conveyor System Implementation:

The following factors if well considered can help the manufacturer make an appropriate decision about the conveyor system to use.

Capacity: It must meet the conveyor capacity of the intended production rate. The conveyor must have the capacity to produce at the required rate.

Speed: The velocity on the conveyors should also be adopted in a manner that optimizes the production process.

Flexibility: The system should be flexible in handling changes in product mix and changes in production needs.

Reliability: The assembly conveyors should be resistant and need less maintenance as much as possible.

Safety: The system also has to be safe and avoid or meet all the possible risks.

Key Product Recommendations From SZKJ

Lowering Gate Conveyor: The primary function of this control is to guarantee the effective flow of PCBs from one production phase to another.

Wave Exit Conveyor: Constantly offloads the PCBs from wave soldering machines to enhance the working procedures.

PCB Flipper Conveyor: Enables fast thorough processing of PCBs in one and two-sided manner.

Conclusion

Using the existing knowledge of first principles in understanding assembly conveyors and the different available conveyors for SMT production, manufacturers can enhance productivity and improve their SMT lines. This is also concluded that efficient conveyor systems combined with the corresponding hardware can increase the general efficiency and decrease overall expenses and the costs of individual products.

For the best results of your SMT assembly line production factory, consider working with SZKJ which has good experience in the development of conveyor systems. We offer rated solutions where we provide services in designing, manufacturing, and installation of conveyors that meet your needs. Contact us today for a quote to learn how our services can revolutionize your production experience.