Table of Contents

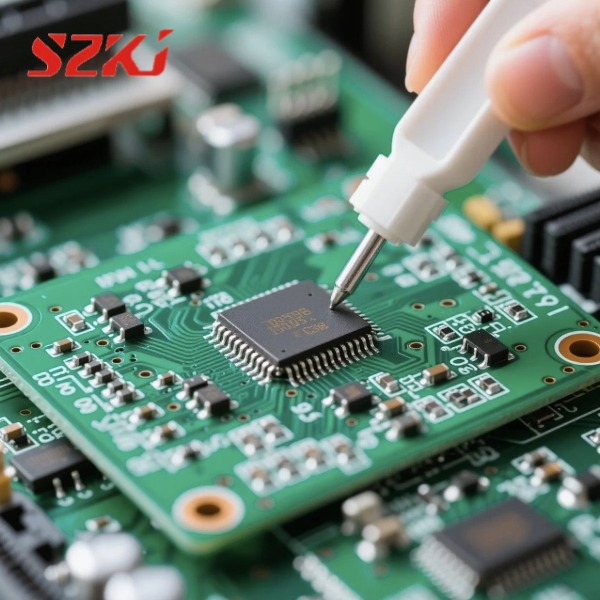

ToggleSMT, also known as surface mount technology, is an automatic tool used in electronics device manufacturing that handles the placing of solder surface components into printed circuit boards, also called PCBs.

Their tasks are to take care of the application of solder paste, adding components correctly, soldering reflows, and melting the solder paste to generate electrical connections.

SMT machines are so important because of their ability to handle small, complex components, which helps in large amounts of production with constant quality.

This article will educate you on the different types of SMT machinery, where to get them, and how to get the best-quality ones.

Types of SMT Machines

1. The Pick-and-Place Machine

This machine has the purpose of picking up the electronic components and placing them in the right positions. It uses the circuit board’s layout to perfectly drop the SMDs in the exact places.

2. The Solder Paste Screen Printer

This handles the printing solder paste before the picking and placing, which consists of two parts: a squeegee blade and a PCB holder, and the squeegee takes care of the poured solder paste in the direction of the PCB.

3. The SMT Machinery Baking Oven

Once the SMDs are placed, the circuit board must undergo a system called baking ovens or SMT curing that will make the SMDs stick to the surface of the PCB, by providing a high temperature that will melt the solder paste, helping to make it a conducting adhesive.

4. The Reflow Soldering Machine

This takes care of the permanent duty of attaching the SMDs to the PCB, as well as the preheating of the electronic components, melting the solder paste that makes up the enduring joints between the SMDs and the circuit board without any harm to the SMDs.

5. The Solvent Cleaning Equipment

It helps with the cleaning of the soldering mess around the PCB during the soldering procedure on the circuit board.

Points to consider before buying

1. You have to consider the cost of the SMT machines

2. The performance and durability of the SMT.

3. Availability of the parts of the machine when faulty.

4. The strength of the component when exposed to duress.

5. ROI guarantee: The guarantee on the SMT machines

Where can you buy high-quality SMT machinery at a competitive price?

Shanzhong Technology provides the best SMT machines in the industry with its cutting-edge technology. Be assured that our SMT machines will be a perfect addition to your manufacturing progress.

Below are some of the SMT machines that you can purchase from us!

1. Fully Automatic Double Track Pickup Machine

- Microcomputer (PLC) control, stable and reliable work.

- Touch screen control interface, easy operation

2.UL-250M-SZ Fully Automatic Plate Drawing Machine

- Mount loading device on circuit board of production line

- Special sheet metal structure, better understanding of the MAGAZINE operation status

3. LD-250M-SZ Automatic Loading Machine

- Adopts cylinder pushing plate structure, pushing plate strength and speed can be adjusted

- Auxiliary positioning brake system, accurate positioning, fast lifting speed, high production efficiency

4. NG BUFFER-M-SZ Multi-Function Cache Machine

- SMT testing equipment after the NG / OK device

- Special sheet metal structure for better understanding of MAGAZINE operation status.

5. MFC-M-SZ Multi-Function Cache Machine

- Board loading device for SMT production line circuit boards

- Special sheet metal structure, a better understanding of the MAGAZINE operation status.

-768x768.jpg)