Table of Contents

ToggleWith a world of vehicles moving faster, there is an ever-increasing need for efficiency, reliability, and more sophisticated electronic systems than ever. With what is currently becoming more and more high-tech features in modern vehicles from safety measures to infotainment systems, whatever is produced under these needs has to be as sophisticated as possible. Thus, among several such technologies, the industry effectively utilized for this purpose, Surface Mount Technology, or SMT is one of the most important.

SMT changed the way a huge number of electrical components are assembled into much smaller, highly intricate systems with high precision. The use of the SMT line machine is very predominant in the automotive area, where compactness, durability, and reliability are paramount. These machines place tiny electronic components onto the PCBs that control a variety of critical functions of modern vehicles. From the engine control units and the tire pressure sensors to a whole host of other electronic systems, SMT line machines will allow the automotive industry to deliver increased electronic demands that modern consumers are demanding.

Let’s explore deeply!

What is SMT in the Automotive Industry?

Modern automotive manufacturing could not do without Surface Mount Technology (SMT). This is particularly relevant to the further development of vehicle electronics, which encompasses not only safety and infotainment but much more, among others. Thus, it has become a means of necessity due to effective execution. SMT line machines are at the core of the change, deciding on the assembly of the electronic components of various automobile systems. In fact, SMT increases reliability and size reduction while achieving high performance by mounting the electronic components directly onto printed circuit boards (PCBs).

Role of SMT Line Machines in the Automotive Industry

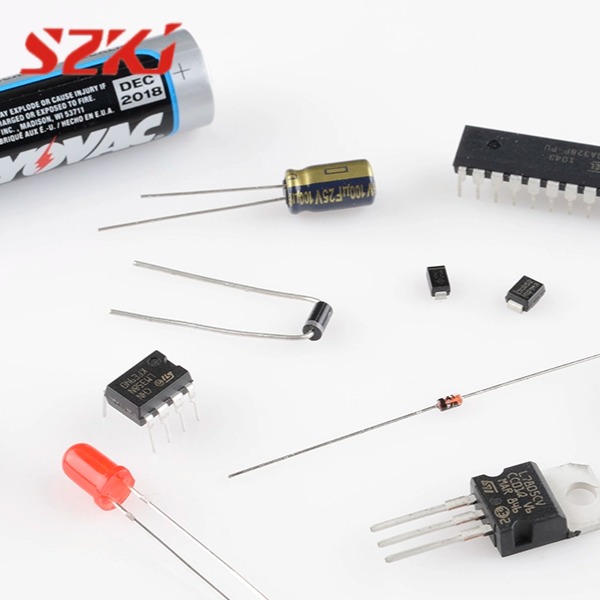

In the automotive industry, SMT line machines are a necessity and make the complex assembly of electronic modules. These line machines place elements like resistors, capacitors, and microchips on PCBs handling all the body functions, including the engine control units, airbag deployment system, braking system, and so on.

The space efficiency of the SMT line machines permits increased components to be assembled in a smaller footprint. This is an important requirement for modern automobiles that consume more space than ever before. Finally, SMT minimizes the manual wiring aspect, thus reducing possible human errors and enhancing reliability. This would be extremely critical in automobiles since safety is of prime importance: wiring failures may result in the malfunctioning of various safety mechanisms.

Practical Applications of SMT in the Automotive Industry

The use of SMT line machines in the automotive industry extends beyond engine control. For example, they are used to make sensors that serve in tire pressure monitoring systems; these are critical components for the optimal health and safety of tires. Another very critical application of SMT in contemporary automobiles is through radar and camera systems applied to adaptive cruise control and autonomous driving.

The installation of SMT in the battery management systems in electric and hybrid vehicles is said to assist in optimizing power distribution and give the battery more efficiency. Such electronic systems which are usually found in the vehicle should be efficient even under extreme conditions such as temperature changes and vibrational stresses.

Infotainment systems have also become a common feature in new-age automobiles. SMT line machine plays a crucial role here as well. The processors, memory chips, and communication modules that ensure smooth connectivity, rich audio quality, and responsive human-machine interfaces, are all assembled through such machines.

Product Recommendations

High-quality SMT line machine is specifically needed for the assembly lines of automotive manufacturing companies that want an upgrade in their assembly. Of course, in this regard, companies like SMT Manufacturing provide several machines and peripheral equipment for challenging automotive companies. What’s more interesting is that on how you assemble an engine control unit or a very complex car infotainment system, the SMT line machines make sure that it is precise, reliable, and efficient in assembling such complex electronics.

Conclusion

SMT hence changed the way of electronics manufacturing in the automotive sector. By using the SMT line machine, the producers can make smaller, more efficient as well as highly reliable electronic components aimed at meeting the broad demands of modern vehicles concerning safety, infotainment, and other advanced systems.

For any auto manufacturer to be ahead of its competitors, SMT line machines play an important role in productivity to be able to upgrade quality and efficiency in the production of processes, facilitating companies to race with the high-speed innovation within automotive electronics.