Table of Contents

ToggleIn modern electronics manufacturing, reflow soldering plays a crucial role in ensuring that circuit boards are properly assembled. This process is integral to the production of high-quality electronic devices. Reflow soldering, along with advanced assembly equipment, allows for the creation of reliable, precise, and durable electronic products. In this article, we will explore the key aspects of reflow soldering and the importance of assembly equipment in the overall manufacturing process.

What is Reflow Soldering?

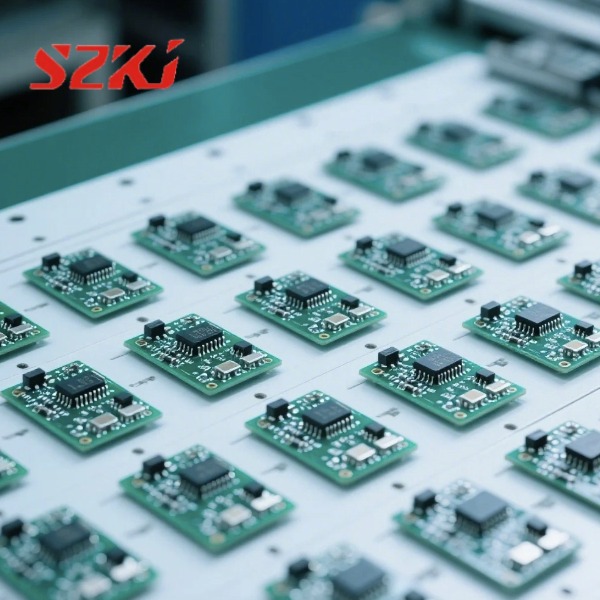

Reflow soldering is a technique used to join electronic components to a printed circuit board (PCB) by melting solder paste. The solder paste is applied to the PCB where components will be placed, and then, the entire assembly is passed through a reflow oven. The oven heats the assembly to a point where the solder paste melts, forming solid connections between the components and the PCB.

This process is widely used in the surface-mount technology (SMT) production line, as it allows for quick and efficient soldering of a large number of components. Reflow soldering has become the go-to method in the electronics industry due to its consistency and precision, ensuring that components are securely attached to the PCB with minimal defects.

The Role of Assembly Equipment in Reflow Soldering

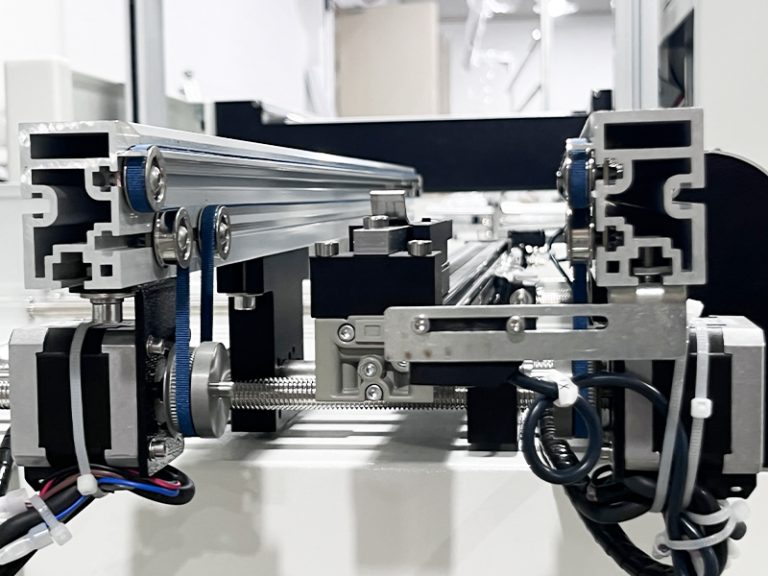

The success of the reflow soldering process depends heavily on the quality and performance of the assembly equipment. From applying solder paste to positioning components and placing the PCB into the reflow oven, each stage requires specialized machinery to ensure high precision and efficiency.

- Solder Paste Printer: The first step in the reflow soldering process involves applying solder paste to the PCB. A solder paste printer ensures that the paste is evenly applied to the designated areas. This step is critical for achieving reliable solder joints, as uneven paste application can lead to cold solder joints or bridging between components.

- Pick-and-Place Machine: Once the solder paste is applied, the next step is placing the electronic components onto the PCB. A pick-and-place machine automatically picks up components and places them accurately onto the PCB. This machinery ensures that components are placed in the right orientation and position, which is essential for achieving optimal soldering results during reflow soldering.

- Reflow Oven: The heart of the reflow soldering process, the reflow oven uses a series of controlled heating zones to gradually heat the PCB and solder paste to the appropriate temperature for melting. The oven’s ability to maintain precise temperature profiles is essential for avoiding damage to components and ensuring that solder joints are properly formed.

- Inspection and Quality Control Equipment: After reflow soldering, it is important to inspect the assembly to ensure the quality of the solder joints. Automated optical inspection (AOI) systems and X-ray inspection machines are commonly used to detect defects like cold solder joints, missing components, or solder bridges. These systems ensure that only the highest-quality assemblies proceed to the next stage of production.

The Benefits of Using Reflow Soldering with Advanced Assembly Equipment

Integrating reflow soldering with modern assembly equipment offers several advantages:

- High Precision: Advanced equipment, such as pick-and-place machines and reflow ovens, ensures that components are placed with high precision and that solder joints are consistently formed. This reduces the chances of defects and improves the overall quality of the final product.

- Increased Efficiency: Automated systems for solder paste application, component placement, and reflow soldering increase the speed and efficiency of the manufacturing process. This helps manufacturers meet tight production deadlines and reduce labor costs.

- Cost-Effectiveness: Although the initial investment in advanced assembly equipment may be significant, the long-term benefits in terms of reduced defects, higher yields, and faster production times make it a cost-effective solution for high-volume manufacturing.

- Flexibility: Reflow soldering can be used for a wide range of electronic components, including fine-pitch components and small-outline components. The flexibility of reflow soldering, when combined with modern assembly equipment, makes it suitable for a variety of products and industries.

Conclusion

Reflow soldering is an essential process in electronics manufacturing, ensuring that components are securely attached to PCBs with reliable solder joints. The integration of advanced assembly equipment, such as solder paste printers, pick-and-place machines, and reflow ovens, plays a vital role in optimizing the efficiency and precision of the process. Manufacturers who invest in high-quality assembly equipment can improve their production quality, reduce defects, and achieve faster turnaround times.

For those looking to enhance their manufacturing capabilities, SZKJ provides top-tier assembly equipment designed to streamline the reflow soldering process. With their advanced technology and reliable service, SZKJ ensures that your production line operates smoothly and efficiently, meeting the highest standards in the electronics industry.