Table of Contents

ToggleIntroduction

Due to the rising need for accurate and efficient electronic assembly, SMT pick & place machines have found an ever-increasing role in the renewable energy sector. These machines are essential for making parts for renewable energy sources, such as electric cars, wind turbines, and solar panels. By examining the advantages, uses, and product suggestions of SMT pick & place machines, this article explores how these machines are revolutionizing the new energy sector.

Making Explanation of smt pick & place machine

Making Explanation of smt pick & place machine

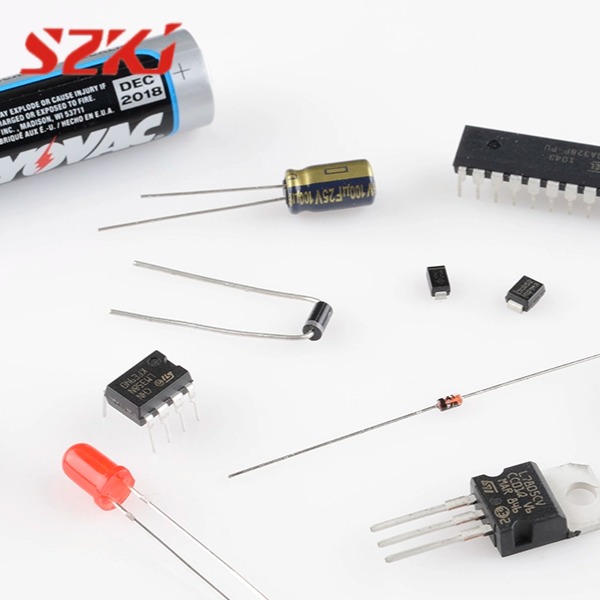

Automatic equipment called SMT pick & place machines are specifically engineered to install electrical components onto PCBs. To guarantee the dependability and functionality of electrical devices, they use sophisticated vision systems and robots to position components precisely. These machines aid in the new energy industry’s efforts to simplify production and reduce expenses.

Applications in the New Energy Industry

Solar Power: Smt pick & place machines play a crucial role in the assembly of solar control systems and inverters in the solar energy production process. For these parts to work at their best, you have to put all the electrical components in just the right spots. One way to improve solar inverters’ performance is to use microcontrollers and power management. Due to the precision of SMT machines, fewer assembly-related errors occur, resulting in superior solar products.

Energy from Wind: Automated SMT pick & place machines are useful in wind turbine technologies as well. The control units and sensors that makeup wind turbines’ electronic systems need to be put together with extreme care so they can endure severe weather. It is critical for the dependability of wind turbine operations that components be put precisely on the PCB, and SMT machines allow manufacturers to accomplish just that. Overall system efficiency is improved, and maintenance costs are reduced, according to this accuracy.

Autonomous Electric Vehicles: Complex electrical components, including power distribution units, infotainment systems, and battery management systems, are vital to the electric vehicle industry. SMT pick & place machines make it easy to quickly assemble these complicated electronic parts, which helps manufacturers of electric vehicles keep up with the rising demand. These machines are especially useful in the fast-paced automobile industry since they can handle a wide range of component sizes and types.

Advantages of SMT Pick & Place Equipment

Enhanced Effectiveness: Improved output is a key benefit of surface mount technology (SMT) pick & place machines. The machines can place thousands of components per hour, which is much faster than manual assembly techniques. To keep up with the new energy sector’s burgeoning demand, this rate is crucial.

Improving Accuracy: Assembly mistakes are less likely to occur when using SMT machines due to their precision. For uses where seemingly little mistakes can have a major impact, precision like this is essential. Manufacturers can enhance product reliability by consistently placing components appropriately.

Time and Money Saved: Although SMT pick & place technology may require a sizable upfront investment, it more than pays for itself in the long run. Automated assembly cuts down labor expenses and waste caused by mistakes or faulty items to a minimum. Consequently, producers can improve their ROI in the long run.

Real-World Cases

Real-World Cases

A Case Study on the Manufacturing of Solar Panels

An SMT pick & place machine was integrated into the production line of a prominent solar panel manufacturer. Automation of the inverter control board assembly process increased output quality while decreasing assembly time by 30%. Because of this upgrade, they were able to increase production without lowering quality standards, which helped them fulfill the increasing demand.

Electric Vehicle Production: A Case Study

An electric vehicle manufacturer’s battery management system assembly line now uses SMT pick & place technology. Because the machine could accommodate components of varying sizes, it greatly simplified their operations. They improved the system’s reliability and cut manufacturing time by 25% as a result.

Conclusion

The new energy industry has made a huge leap forward in manufacturing technology with the integration of SMT pick & place machines. Reliable electronic components utilized in solar energy systems, wind turbines, and electric cars rely on their capacity to increase efficiency, precision, and cost-effectiveness. Companies that want to be successful in the sustainable energy solutions industry will need to invest in modern SMT technology to keep up with the rising demand for these products.