Table of Contents

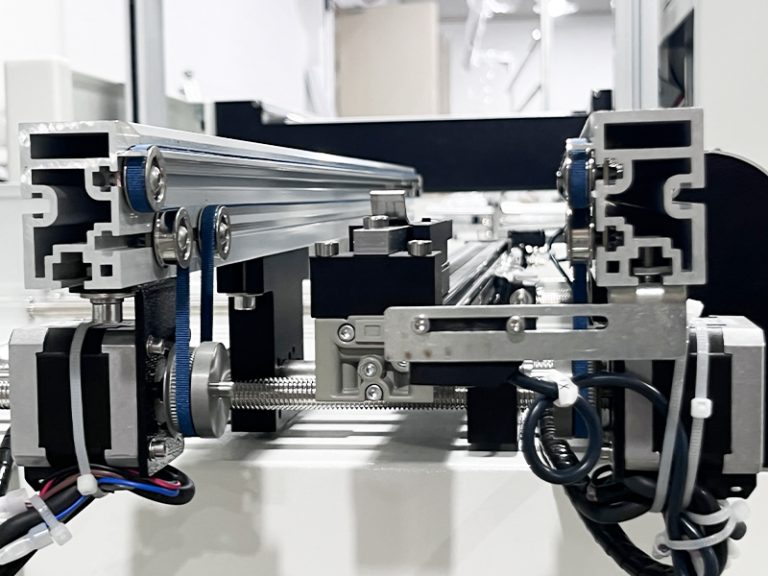

ToggleIn the realm of high-precision electronics manufacturing, a smooth and efficient Surface Mount Technology (SMT) production line is crucial. Although the SMT pick and place equipment

is essential, peripheral supporting equipment is equally important in enhancing productivity, ensuring quality, and maximizing output.

The most common uses for SMT pick and place equipment

The most common uses for SMT pick and place equipment

Speeding Up Production

One of the biggest perks of SMT pick-and-place equipment is how it speeds up production. Imagine trying to assemble a puzzle by hand. It takes time, especially with tiny pieces. Now, picture a machine doing that job at lightning speed. That’s exactly what these machines do for electronic components. They can place thousands of parts in just a few hours, making assembly lines much more efficient.

Enhancing Precision

When it comes to electronics, precision is crucial. Even a small misplacement can lead to major issues. SMT pick and place machines are designed to be incredibly precise. They can accurately position components down to the tiniest measurement. This level of accuracy ensures that every device works as intended, reducing errors and the need for rework.

Supporting Small and Large Batches

Whether you’re making a few pieces or thousands, SMT pick and place equipment is versatile. For small runs, these machines can easily handle different component types without a hassle. For larger batches, they maintain the same level of quality and speed. This flexibility makes them a favorite for businesses of all sizes. It’s like having a Swiss Army knife for electronic assembly!

Improving Quality Control

Improving Quality Control

Quality control is vital in electronics. With SMT pick and place equipment, manufacturers can achieve higher quality standards. These machines often include built-in inspection features. They can check the placement and orientation of components during the process. This means fewer defects make it through the system, resulting in better products overall. Think of it as having a watchful eye ensuring everything is just right.

Reducing Labor Costs

Using SMT pick and place machines can also save money on labor costs. Automating the placement of components means fewer workers are needed on the assembly line. While human workers are still essential for more complex tasks, machines take over the repetitive parts. This cuts costs and allows workers to focus on more important jobs that require a human touch.

Versatile Applications

The uses of SMT pick and place machines extend to various industries. From consumer electronics to automotive components, these machines are everywhere. Each industry has unique needs, but the basic function remains the same. Whether you’re looking at smartphones or car parts, SMT equipment ensures components are placed accurately and efficiently.

Conclusion: An Essential Tool in Electronics Manufacturing

SMT pick and place equipment is a powerhouse in the electronics manufacturing sector. Its ability to speed up production, enhance precision, and support different batch sizes makes it an invaluable resource. As technology continues to evolve, the importance of these machines will only grow. Understanding their common uses helps us appreciate their role in shaping the devices we rely on daily.