Table of Contents

ToggleWhen it comes to CPU and IC chip packaging, both LGA and PGA are widely used formats. While they may appear similar at first glance, these two packaging methods differ significantly in structure, cost, and application. In this article, we explore lga vs pga in detail, comparing them from multiple angles to help you make an informed decision.

Comparing LGA vs PGA

One of the most significant differences between lga vs pga lies in their pin structure and connectivity.

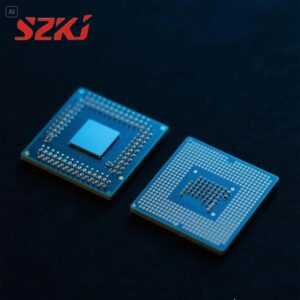

LGA, or Land Grid Array, features flat contact points (or pads) instead of protruding pins. These pads are located on the bottom of the chip and are designed to sit directly onto corresponding pins on the motherboard or PCB. LGA chips are typically soldered using specialized equipment, which makes them more secure but harder to remove or replace without professional tools.

In contrast, PGA, or Pin Grid Array, includes multiple small pins on the bottom side of the chip. These pins are inserted into a matching socket, making PGA chips easier to install and remove. This feature is particularly useful for systems that require frequent upgrades or replacements, such as desktop computers and development boards.

Cost Comparison: LGA vs PGA

The discussion around lga vs pga is incomplete without addressing cost efficiency.

LGA has emerged as a more modern and cost-effective solution, often used in mass production due to its compatibility with automated assembly processes. Because LGA chips are easier to solder using reflow techniques, they help reduce manufacturing time and labor costs. This makes them especially appealing in high-volume electronics manufacturing.

On the other hand, PGA is an older packaging technology that tends to have higher manufacturing costs. The need for precise alignment and the risk of pin damage during installation can add to the overall production expense. While PGA may offer some advantages in terms of convenience, it is generally considered more expensive and less space-efficient than LGA.

Application Comparison: LGA vs PGA

From an application standpoint, lga vs PGA serves different market needs.

LGA is commonly found in high-performance applications such as server processors, modern desktop CPUs, laptops, and embedded systems. Its design supports better thermal and electrical performance, as well as greater packaging density, making it ideal for compact and high-speed devices.

PGA, on the other hand, is still widely used in educational kits, prototyping, and some consumer desktop processors. Its replaceable nature makes it suitable for environments where frequent chip replacement is required or where cost isn’t the primary concern.

Conclusion

In the comparison between lga vs pga, each has its own strengths and weaknesses. LGA is favored for its low cost, high density, and advanced performance, but it requires professional tools for installation. PGA offers easy replacement and installation, but it is often more expensive and less compact.

Ultimately, the choice between lga vs pga depends on your specific application needs, budget, and technical capabilities. Understanding their differences allows for smarter component selection and more efficient product design, especially in the fast-evolving electronics industry.