Table of Contents

ToggleIn modern electronics manufacturing, the efficiency and reliability of PCB production lines are critical to meeting increasing market demands. A well-designed PCB handling conveyor system plays an essential role in streamlining the production of printed circuit boards (PCBs). By automating the transfer and handling of PCBs between various workstations, these systems not only improve efficiency but also enhance product quality and consistency.

Integral Role in PCB Manufacturing

A PCB handling conveyor system is the backbone of PCB production, linking multiple workstations and enabling seamless transitions between critical stages such as component placement, soldering, testing, and inspection. Without it, manual handling would lead to increased errors, slower processing times, and a greater risk of PCB damage. In fast-paced manufacturing environments, these systems ensure a continuous and stable flow of boards, preventing bottlenecks and optimizing overall output.

Key Features and Components

Conveyor Belts

The conveyor belt is the central element of the system, responsible for moving boards across the production line. These belts can be customized in width, length, and material to accommodate different PCB sizes and factory layouts, ensuring maximum adaptability.

Workstations

Strategically placed along the conveyor, workstations are designated zones for specific tasks such as solder paste application, pick-and-place, or visual inspection. The precise alignment and integration of these stations ensure that every PCB passes through the correct sequence without delays.

Automated Component Placement

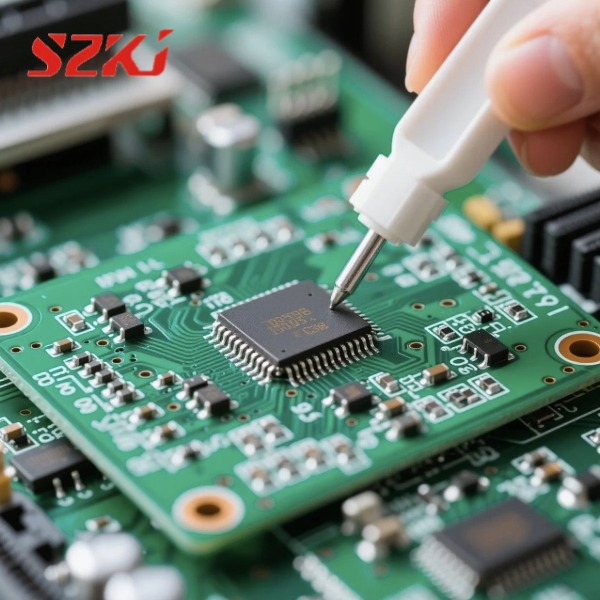

Modern systems incorporate robotic arms or surface-mount machines that automatically and accurately place electronic components onto PCBs. This reduces manual labor and improves the precision and repeatability of component placement.

Soldering and Reflow Stations

Once components are in place, the conveyor transports the PCB to soldering stations equipped with reflow ovens or wave soldering machines. These ensure strong, reliable solder joints, which are essential for product durability and performance.

Testing and Inspection

To guarantee quality, PCB handling conveyors include testing and inspection zones, often equipped with automated optical inspection (AOI), in-circuit testing (ICT), or visual verification systems. These catch defects early and help maintain high product standards.

Buffer Zones

Buffers provide temporary storage for PCBs when downstream stations are occupied. This prevents line stoppages and maintains a balanced production flow, especially useful in high-speed environments.

Control Systems

Advanced control systems monitor the movement of PCBs throughout the line, allowing operators to adjust speed, queueing, and process sequences. This not only enhances visibility but also enables better synchronization across all operations.

Modularity and Flexibility

PCB handling systems are designed to be modular, meaning manufacturers can reconfigure or expand them according to changing production needs. Whether producing small-batch prototypes or scaling up for mass production, the system offers unmatched flexibility.

Benefits of an Integrated System

The integration of a pcb handling conveyor system in a production line significantly improves operational efficiency. It minimizes human error, reduces material handling time, and ensures each board receives consistent processing. The result is a higher-quality product, reduced downtime, and a more agile response to manufacturing demands.

Applications Across the Industry

These systems are widely adopted in electronics manufacturing plants, where high precision and throughput are essential. From consumer electronics to industrial equipment and automotive electronics, a PCB handling conveyor system ensures that each PCB is produced to the highest standards, efficiently and consistently.

Conclusion

A well-engineered PCB handling conveyor system is vital to optimizing modern SMT production. It connects every step of the process—from component placement to inspection—enabling smooth, automated operations that increase quality and throughput. For manufacturers seeking to upgrade their production capabilities, investing in such a system is a strategic move.

If you’re looking to purchase advanced PCB handling equipment, SZKJ offers a wide range of customizable solutions. Visit their website to explore product specifications, configure your ideal system, and place your order directly online.