Table of Contents

ToggleAn assembly line conveyor belt plays a vital role in modern production, efficiently moving products, enhancing workflow, and ensuring consistent quality across small and medium-scale manufacturing processes.

I. What Is an Assembly Line Conveyor Belt?

An assembly line conveyor belt is a mechanical system designed to transport goods, components, or materials along a predetermined route during the manufacturing process. It improves production efficiency by enabling continuous movement of items, reducing manual handling, and optimizing workflow.

In modern manufacturing, an assembly line conveyor belt is widely used in industries such as electronics, packaging, and light manufacturing to handle various stages of production and assembly with precision.

SZKJ is a company that provides customized SMT production lines and conveyor solutions designed to ensure high precision and reliability. Their products integrate proprietary accuracy algorithms to minimize conveyor deviation to one-third of the industry average.

II. Key Types of Assembly Line Conveyor Belts for Small-Scale Production

PVC conveying lines are widely used for transporting goods in light industrial environments. They can be configured as belt lines, chain plate lines, plug-in lines, mesh belt lines, hanging lines, and roller lines. These systems include traction components, bearings, drive units, tensioning devices, and support frames. A PVC conveyor can perform horizontal, inclined, or vertical transport and is often fixed in position. During transport, it may also support specific process operations, making it highly versatile.

Electronic assembly lines are designed for the precise and consistent assembly of electronic components. They provide automated solutions that reduce production time and enhance output quality. Each product passes through the same standardized process, ensuring consistency while lowering operational costs. SZKJ electronic assembly lines are often integrated into SMT production systems to handle tasks between reflow soldering and other key stages.

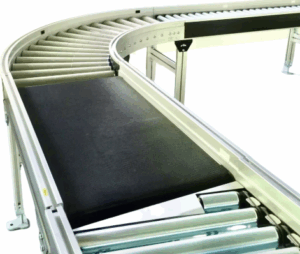

Roller line conveyors, also called roller conveyor systems, are fundamental equipment in various industries, including manufacturing, packaging, and warehousing. They can be designed as straight, curved, or inclined layouts depending on the production environment. Roller line conveyors help improve productivity and reduce manual labor requirements in handling heavy or bulky goods.

III. Working Principle of Conveyor Belts

- Basic Working Mechanism of Conveyor Belts

The working principle of an assembly line conveyor belt involves continuous movement powered by a motorized drive or manual force. Goods are carefully placed on the belt or rollers, which carry them along the intended production path, ensuring smooth material flow.

- Components and Control Systems for Efficient Transport

Key components such as pulleys, motors, and control systems work together to maintain steady transport. Some modern systems also integrate sensors or programmable controls to manage speed, stop points, and alignment, improving accuracy and reducing operational errors.

IV. Manufacturing Process of Conveyor Belts

Manufacturing an assembly line conveyor belt includes material selection, component assembly, and quality testing.

Steps include:

- Assembling the frame, rollers, and drive mechanism.

- Installing the belt or chain system.

- High-quality manufacturing ensures minimal wear, reliable operation, and long service life.

V. Applications of Conveyor Belts

Assembly line conveyor belts are used in a wide range of industries, such as:

- Electronics: for transporting circuit boards and small components.

- Packaging: for moving products through labeling, sealing, and boxing stages.

- Warehousing: for sorting and distributing goods efficiently.

- Light Manufacturing: for transporting semi-finished products between production steps.

In addition to these sectors, assembly line conveyor belts are increasingly adapted for small-scale production units, research facilities, and modular manufacturing lines. Their ability to integrate with automated control systems and robotic arms makes them suitable for both traditional and emerging industries that require flexibility and rapid reconfiguration.

VI. Conclusion

Assembly line conveyor belts are an essential element of modern production systems. They streamline workflows, reduce energy waste, and improve overall efficiency across industries. Among the many suppliers in this field, SZKJ has established itself as a provider of customized SMT conveyor solutions that emphasize precision and reliability without compromising adaptability.

By continuously refining its technology and expanding its global reach, the company contributes to the evolution of efficient and flexible manufacturing processes. With the growing need for scalable, low-maintenance, and cost-effective systems, the role of assembly line conveyor belts will continue to expand, serving as a critical backbone of industrial automation in the years to come.