Table of Contents

ToggleWhen you’re building electronics for life-saving equipment, there’s no room for error. That’s where SMT AOI machines come in—they help catch mistakes early, and ensure that every component is accurate and reliable. In this post, we’ll dive into 4 practical ways SMT AOI machines are used in medical device manufacturing. We’ll show you how they can improve quality control, speed up production, and keep you compliant with industry standards.

Let’s get right in!

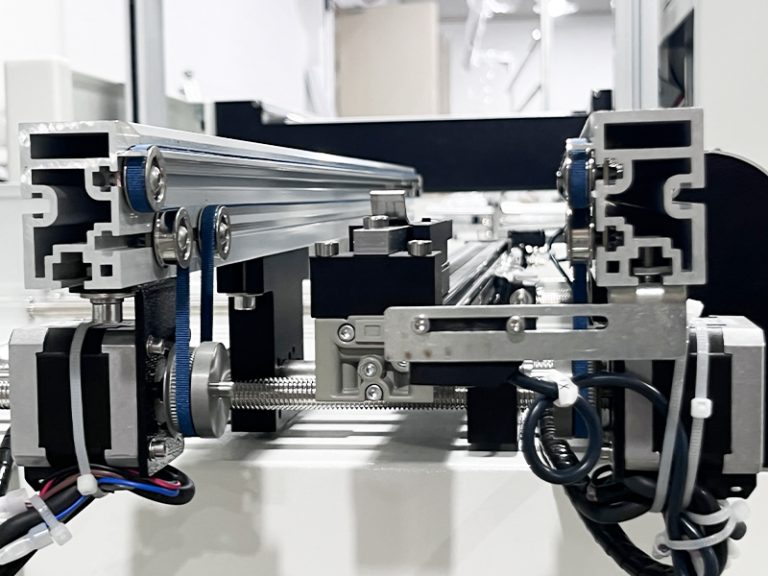

What are SMT AOI Machines?

SMT AOI machines are advanced optical inspection systems designed to analyze the surface mount technology (SMT) assemblies before they are finalized. Using high-resolution cameras and sophisticated software, these machines compare the physical attributes of each component against defined parameters and quickly identify defects such as misalignments, soldering issues, or missing parts.

Applications of SMT AOI Machines in the Medical Field

Precision is important in the medical field, and SMT AOI machines offer traditional inspection methods to improve the integrity of medical devices. Here are some ways in which they contribute to the various stages of the production of medical devices.

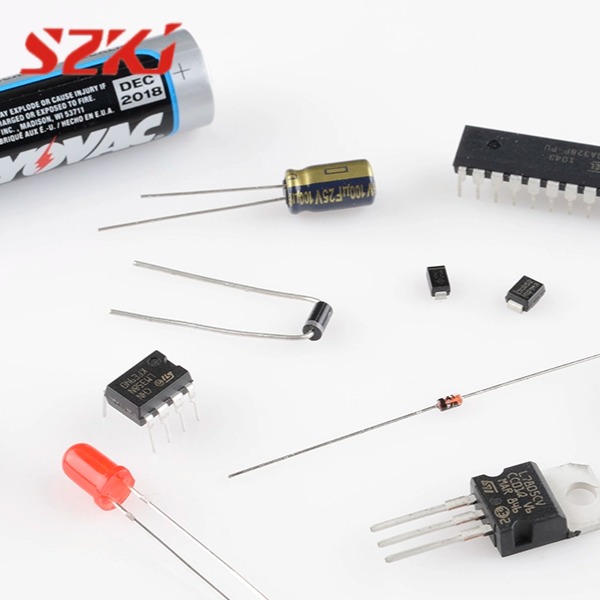

- Medical Devices PCBs

SMT AOI machines are used in the production of printed circuit boards (PCBs) for medical devices. They ensure that each solder joint and component placement adheres to strict specifications.

This reduces the risk of failure in critical equipment such as heart monitors and infusion pumps, where accuracy can directly impact patient safety.

- Diagnostic Equipment

In diagnostic equipment, SMT AOI machines help inspect the intricate circuitry found in devices such as MRI machines and ultrasound equipment. Any inconsistency in these delicate systems can lead to inaccurate readings or device malfunction, potentially delaying diagnosis and treatment for patients.

By catching flaws early, SMT AOI machines improve the performance of diagnostic tools that are vital for timely medical interventions. For example, if a solder joint is poorly executed or a component is incorrectly placed, the SMT AOI machine will flag it for immediate correction, and prevent further downstream complications.

- Surgical Instruments

The precision of surgical instruments is vital for successful procedures. SMT AOI machines assist in inspecting the electronic components embedded in robotic surgical systems and other advanced surgical instruments. These systems often contain intricate wiring and sensors that must operate smoothly to ensure the safety of patients during operations.

By integrating SMT AOI machines into the manufacturing process, engineers like you can verify that each component meets rigorous quality standards, and reduce the likelihood of instrument malfunction during critical moments in surgery.

- Wearable Medical Devices

Wearable medical devices like glucose monitors and ECG sensors need to be constantly accurate. Given that many of these wearables are designed to provide real-time health data, any error in the electronic assembly could lead to severe consequences for users. To ensure this does not happen, SMT AOI machines are employed to check for correct component alignment and signal integrity, allowing engineers like you to detect potential failures before the devices reach the market.

This not only guarantees user safety but also solidifies the trustworthiness of the wearable technology.

The Bottom Line

SMT AOI machines have become an invaluable asset in medical device manufacturing. Their ability to detect minute errors that could lead to disastrous failures has transformed medical quality assurance processes positively. And beyond just ensuring safety, they also bring a level of performance and speed to production lines that were previously unimaginable.

Want to know more? Contact us today!